BCS Automation is committed to the continual development of quality products and process solutions that are tailored for industrial organizations worldwide. Past industrial automation projects include: system design/build, software development, project management, custom control equipment, operator training, systems analysis, and evaluation. Regardless of the scale or scope of the project, BCS’s goal is to provide clients with the opportunity to reduce expenses, increase production, meet environmental requirements, and improve profitability.

Our engineering team offers comprehensive and innovative solutions to industrial automation challenges with competitive pricing and a commitment to schedule deadlines. Respecting client targets is of the utmost importance to BCS and we strive to meet or exceed the schedule. When professional industrial automation solutions are required, BCS can be relied upon to supply fully functional, cost effective systems and services essential to the reliable processing of our customer’s product.

BULK MATERIAL HANDLING

After 30 years of operating in the field of automation, BCS understands the concerns associated with the transportation of loose bulk material. By integrating reliable electrical automation systems with bulk material equipment, we aim to increase handling operations in a safe and efficient manner. Our engineering team is experienced with automation systems that are essential to the operation of conveyors, pumps, compressors, and vacuum loaders. When automation solutions are required to haul or ship bulk material, BCS can be depended on to provide the products and services to overcome any obstacle.

INDUSTRIAL MANUFACTURING

BCS works with industrial manufacturing organizations to increase efficiencies by incorporating automation systems into the primary areas of manufacturing. When an industrial automation project comes forth, our engineering team analyzes, designs, and manufactures a comprehensive product that is tailored to each specific situation. BCS aims to produce turn-key solutions that reduce labour cost while simultaneously increasing precision and accuracy in the various sectors of industrial manufacturing.

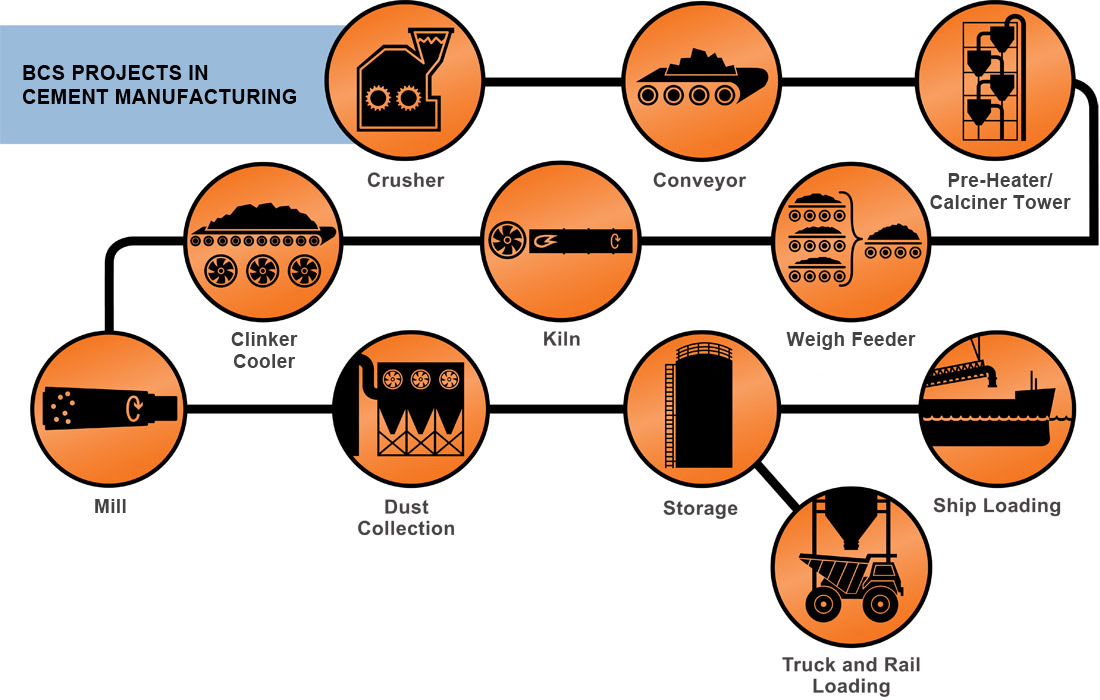

CEMENT INDUSTRY

BCS has established strong relationships with international cement companies. Our commitment to serving the automation needs of the cement industry has resulted in a vast accumulation of experience and expertise in this sector. With over 20 years of experience working on cement processing projects from upgrades to new capital installations, BCS can offer expert advice on electrical distribution and motor control, process control automation as well as Distributed Control Systems (DCS), including Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition Systems (SCADA), and Human Machine Interfaces (HMIs). Past projects include plant-wide environmental emissions monitoring and dust control projects. Overall, our engineering team is prepared to troubleshoot and overcome any automation challenge regardless of where it is occurring over the entire spectrum of the cement manufacturing process.

Crusher

BCS has an advanced level of expertise in providing process control, engineering and instrumentation for primary and secondary crushers. This includes impact, cone, and jaw type crushers. Past projects include upgrade and new installations to achieve increased capacity and greater tons per hour.

Conveyors

BCS has complete automation solutions providing robust process control, engineering and instrumentation for all types of conveyors including belt conveyors, overland conveyors, screw conveyors, bucket elevators and drag conveyors. Upgrade projects to achieve increased capacity and new installations include long overland conveyors to eliminate the need for trucking. Design and installation of CCTV for monitoring flow of material and product spillage. Past projects also include low and medium voltage drive systems and multiple drives on one belt.

Pre-Heater/Calciner Tower

BCS capabilities include process control and engineering for the critical areas of temperature, pressure combustion, emissions monitoring, and control in the pre-heater tower.

Kiln

Successful kiln upgrades have been a big part of the history BCS projects. These projects include burner control and management (indirect firing) for fuel cost reduction, drive systems electrical engineering, internal kiln temperature monitoring, berring monitoring for temperature and lubrication, fuel processing and kiln cooling. Environmental projects include integration of SNCR (Selective Non Catalytic Reduction), dry lime feed, ammonia injection and active carbon injection systems for emissions control. Product formula projects such as alkali bypass and CKD (Cement Kiln Dust).

Clinker Cooler

BCS capabilities include specialized process control and engineering, for temperature monitoring and control during the clinker cooling process. Automation projects in this area also encompasses speed of cooler drives, alarms relating to over-load, low pressure, flow conditions, and control for cooling as required.

Weigh Feeder

BCS’s project experience covers projects with apron, belt, and vibratory feeders. Weigh Feeder engineering and process control capabilities include accurate volume and weight measurement for feed rate control, and expert VFD control.

Mill

BCS provides the automation expertise to achieve enhanced control of the grinding and milling process from raw to finish mills. BCS experience includes ball mills, hydraulic roller presses and vertical roller mills. Knowledgeable control and monitoring of separators, feed systems and recipe management for various cement specifications.

Dust Collection

BCS has a full range of plant-wide process control and engineering experience with dust collection systems (cyclone) including kiln, mill and cooler bag-house and dust removal solutions throughout cement production phases.

Storage

Projects automating dome and silo storage include product filling control, discharging, monitoring, and level indications using reliable ultrasonic or radar technologies. BCS solutions for stored product, enables safe and efficient remote handling and analysis.

Ship, Truck and Rail Loading

Ship to shore wireless communication projects for loading and unloading have successfully linked a ship to/from a land based terminal enabling automated monitoring and controlling capabilities from both locations. BCS’s expertise with belt scale systems has successfully concluded projects requiring accurate and consistent weighing and moving of bulk materials. Wireless communication projects for loading and unloading trucks and rail cars have successfully linked these cement carriers to terminals for labour saving remote monitoring and control.